|

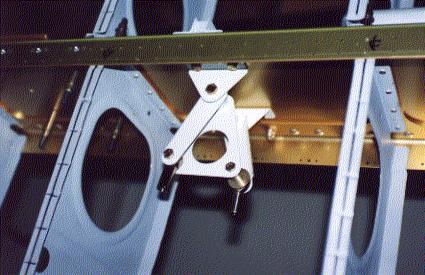

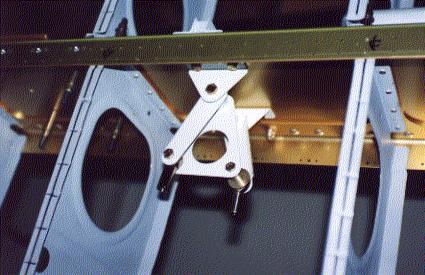

Here is the aileron bellcrank assembly. It all comes powder coated

now, which is nice. |

|

And here is the wing tie down bracket. It is part of the same

assembly as the aileron bracket above, but on the other side of the main

spar. |

|

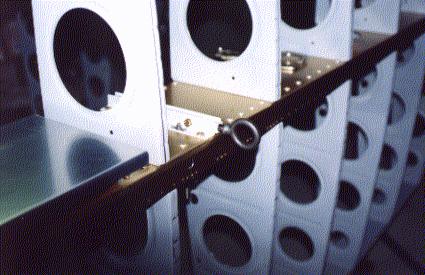

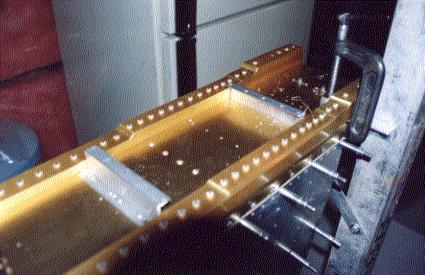

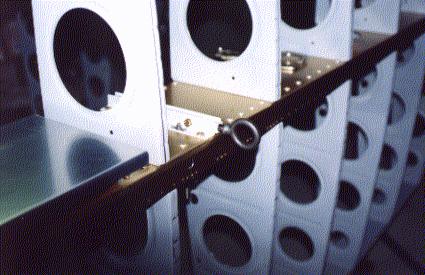

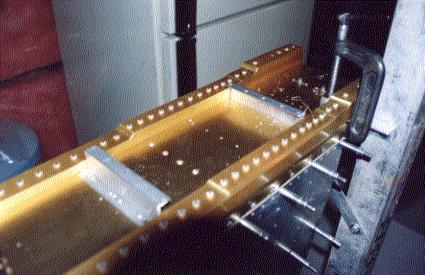

Here I have used cargo straps and pieces of oak scrap to hold the skins

down while I drill them to the ribs. |

|

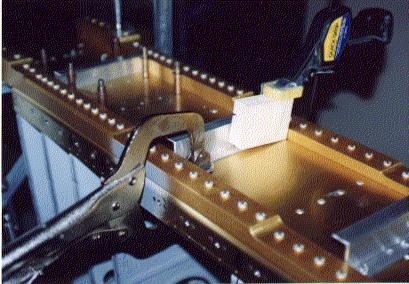

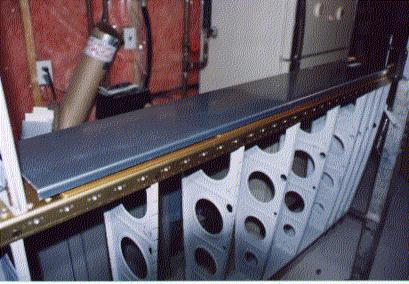

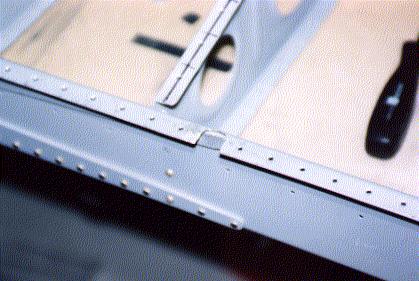

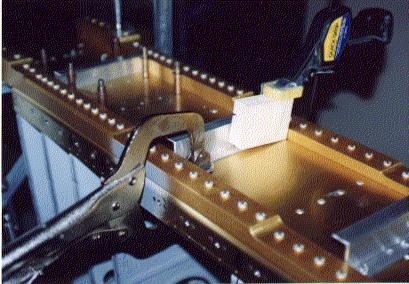

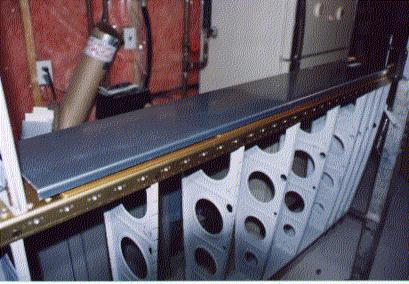

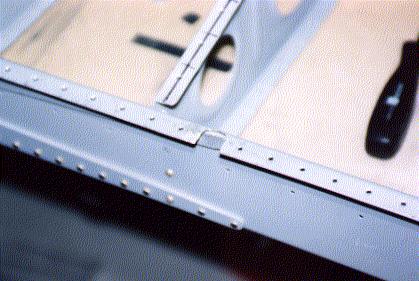

And this is what it looks like once the skins are all drilled on.

The fuel tank is on the far end. |

|

You have to drill the fuel tank attach "Z" brackets to the spar. |

|

The fuel tank rear baffle sits on top of the "Z" brackets (note the

beer fridge in the background). |

|

Another view of the "Z" brackets once they are drilled on. |

|

Putting those 6 foot pieces of threaded rod through all of the leading

edge and tank ribs can be a major pain in the a**. So, I used s short

piece of threaded rod to position a nut and washer on either side of a

rib, then used hockey shin pad tape to fasten the nut and washer firmly

to the rib. I then clecoed the ribs to the spar, and chucked the

long threaded rod in my drill.

Using a medium speed, I just spun the rod onto the ribs, took the tape

off, and tightened the nuts once the ribs were straight. Voila. Takes

less than a minute a rib to tape the nuts and washers on, then about a

minute or two to spin the rod in using the drill. |

|

Pretty dark picture (I don't think the flash went off), but it shows

a pristine fuel level sender on the right, and a completed one on the left. |

|

Here I have drilled and clecoed the fuel tank stiffeners to the right

fuel tank skin. |

|

These are in the inboard ribs, once they have been, Pro-Sealed.

UGGHH! I found doing these things was the worst part of the whole process.

The rest of the sealing was dead easy. |

|

Here are the access panels for the end ribs. Again, dead easy. |

|

This is the right tank skin with the stiffeners in place. Use

a small wire brsh to really scuff up where the ribs and stiffeners go.

This will provide a much better bonding surface for the Pro-Seal. |

|

And this is the filler neck. Kind of a pain in the butt to back

rivet. Make sure to orient the neck the right way (there is a front).

I needed to bend mine just a little bit more to make it fit right. |

|

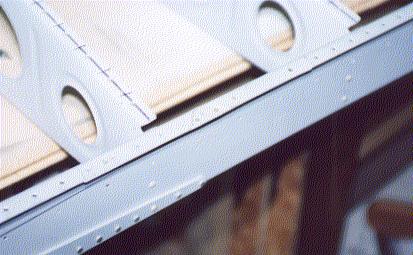

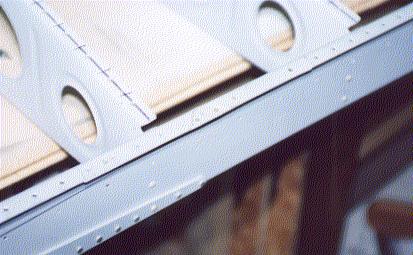

Now, my first major OOPS!! I was using a pneumatic squeezer to dimple

the trailing edge of the wing when it grabbed the rear spar doubler, and

in about a millisecond knarled the flange. I was heart sick. |

|

Here you can see where the squeezer grabbed the doubler. |

|

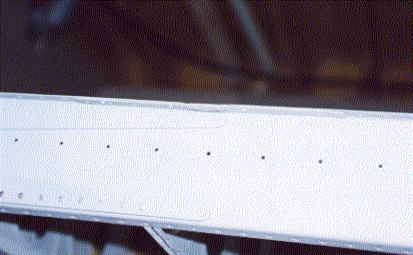

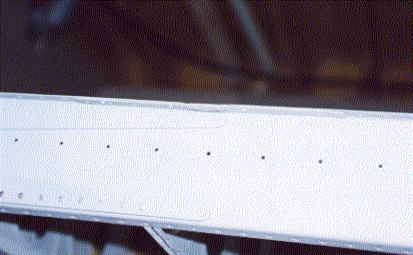

It is hard to make out in this picture, but this is the fix I had Andy

at Van's approve. I cut out the damaged part of the flange.

I made a 6" wide doubler piece to go under the flange with 5 skin rivets

and two keeper rivets on either side of the hole. |

|

I then made a filler piece to go in the gap in the flange, and riveted

that in place. The trailing edge came out quite smooth. Man,

dodged that bullet! |

|

|